Drone How Mini Drone Gimbals Work guidance has gotten complicated with all the outdated regulations and conflicting advice flying around. Here’s what you actually need to know.

Stabilized footage from a drone weighing under 250 grams seems almost magical. The gimbal systems that make this possible represent remarkable engineering—delivering professional-grade image stabilization in packages weighing just a few grams.

How Mini Drone Gimbals Work

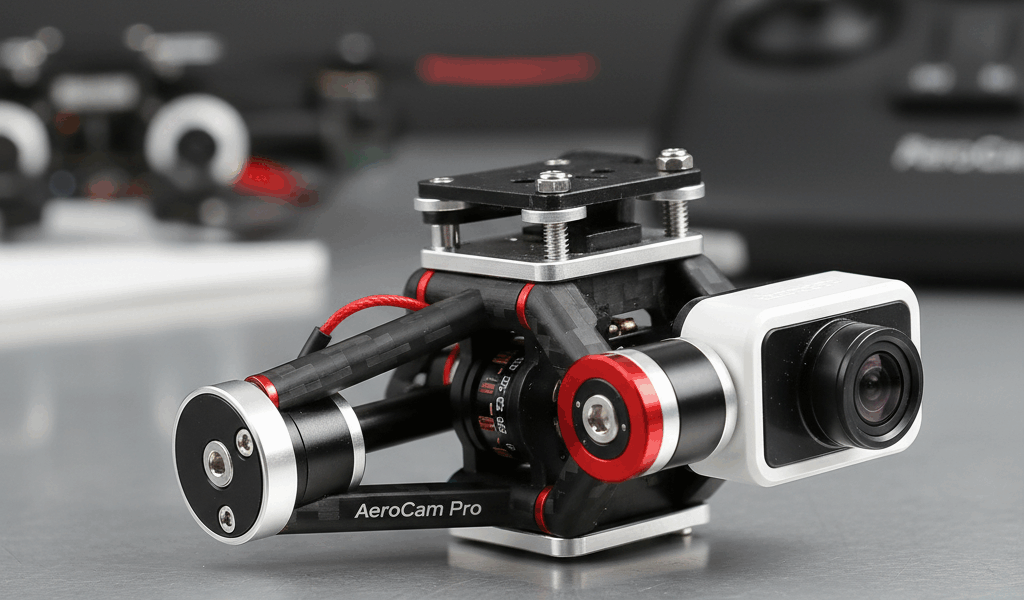

A gimbal isolates the camera from aircraft movement using motorized pivots that counteract rotation in real time. Sensors detect motion, processors calculate corrections, and brushless motors execute adjustments faster than your eye can perceive. The result transforms jerky flight movement into smooth, cinematic footage.

Most sub-250g camera drones use 3-axis gimbal systems that compensate for pitch, roll, and yaw movement. This three-dimensional stabilization handles everything from wind buffeting to aggressive maneuvers, keeping the horizon level and the subject centered regardless of what the aircraft does.

Weight Engineering Challenges

Every gram dedicated to gimbal hardware comes directly from your weight budget for batteries, cameras, or structural components. Gimbal engineers face intense pressure to minimize mass while maintaining stabilization performance.

The DJI Mini series exemplifies this balance. The Mini 4 Pro’s gimbal weighs approximately 15 grams while stabilizing a 1/1.3-inch sensor camera. Achieving this required custom motor designs, precision-machined aluminum arms, and proprietary control algorithms that maximize performance from minimal hardware.

Cheaper alternatives often sacrifice gimbal quality to hit weight targets. Motors lack precision, arms flex under stress, and control algorithms introduce subtle jitter that only appears in finished footage. These compromises explain price differences between seemingly similar specifications.

Mechanical vs Electronic Stabilization

Not all stabilization requires mechanical gimbals. Electronic Image Stabilization (EIS) processes footage digitally to remove shake, cropping into the image to create smooth output without moving parts.

EIS weighs nothing and costs little to implement. However, it sacrifices image quality through cropping and can create unnatural “jello” effects during rapid movement. For serious videography, mechanical gimbals produce superior results despite their weight and complexity.

Some mini drones combine both approaches—mechanical stabilization for major corrections and electronic refinement for remaining micro-vibrations. This hybrid approach extracts maximum smoothness from minimal gimbal hardware.

Axis Configurations Explained

Gimbal specifications reference axis count—typically 1, 2, or 3 axes. Understanding what each configuration provides helps evaluate different drone options.

Single-axis gimbals stabilize only pitch (tilt up/down). These simple systems keep the horizon somewhat level during forward flight but cannot correct for roll or yaw movement. Budget drones sometimes use single-axis systems to minimize cost and weight.

Two-axis gimbals add roll stabilization, keeping the horizon level during banking turns. This configuration handles most common flight movements adequately but struggles with yaw-induced shake during panning or wind gusts.

Three-axis gimbals represent the gold standard for aerial videography. Full pitch, roll, and yaw compensation produces footage indistinguishable from professional cinema rigs. Nearly all serious sub-250g camera drones now include 3-axis systems.

Motor Types and Performance

Gimbal motors differ from the propulsion motors that fly the drone. These precision brushless motors require extreme accuracy—correcting movements measured in fractions of a degree within milliseconds.

Quality gimbal motors use neodymium magnets and precision windings that respond instantly to control signals. Cheaper motors with looser tolerances introduce lag between detected movement and correction, creating subtle shake that ruins otherwise smooth footage.

Motor size represents another weight trade-off. Larger motors provide stronger correction force but add grams to the system. Engineers optimize motor sizing for specific camera weights—a gimbal designed for a light sensor won’t stabilize heavier optics effectively.

Control Algorithms Matter

The software controlling gimbal motors determines real-world performance as much as hardware quality. Sophisticated algorithms predict movement, anticipate corrections, and blend multiple sensor inputs for smoother output.

DJI’s gimbal algorithms benefit from decades of refinement across millions of units. This software maturity explains why DJI drones often outperform competitors with similar hardware specifications. The motors and arms might match, but control software separates adequate stabilization from exceptional smoothness.

Firmware updates can improve gimbal performance on existing hardware. Manufacturers occasionally release algorithm improvements that enhance stabilization without hardware changes—a compelling reason to keep drone firmware current.

Protecting Gimbal Mechanisms

Gimbal components rank among the most fragile elements of any camera drone. Thin motor shafts, precision bearings, and calibrated sensors cannot survive impacts that the airframe handles easily.

Always use gimbal covers during transport. These protective shells lock the gimbal in a fixed position and shield delicate components from compression or impact. Flying without installing the cover risks damage; transporting without the cover virtually guarantees eventual problems.

Gimbal calibration can drift over time or after minor impacts. Most drones include calibration routines in their apps—run these periodically or whenever footage shows unexpected drift or horizon issues.

Temperature and Environmental Effects

Gimbal performance varies with temperature. Cold conditions thicken lubricants, stiffen materials, and slow motor response. Extreme heat can trigger thermal protection that limits gimbal movement to prevent motor damage.

Allow gimbals to warm up in cold conditions before demanding professional-quality footage. A few minutes of idle operation brings components to operating temperature. Forcing immediate aggressive use risks poor results or mechanical stress.

Humidity and salt air accelerate bearing wear and motor corrosion. After flying in marine environments, wipe down gimbal components and store in dry conditions. Long-term exposure without maintenance leads to premature gimbal failure.

Upgrading Gimbal Performance

Unlike other drone components, gimbals rarely accept user upgrades. The tight integration between camera, motors, and control systems makes swapping components impractical for most users.

When gimbal performance becomes limiting, upgrading to a newer drone model typically provides the only practical improvement path. This integration explains why serious videographers invest in current-generation aircraft rather than attempting to extend older platform capabilities.

The Weight-Quality Trade-off

Gimbal systems in sub-250g drones represent extraordinary engineering achievements. Manufacturers compress technology that once required heavy, expensive cinema equipment into packages weighing under 20 grams. This miniaturization enables the portable, regulation-friendly drones that have revolutionized aerial videography.

Understanding gimbal limitations helps set realistic expectations. The physics of stabilization don’t change at smaller scales—lightweight gimbals compensate for less movement than heavier systems. Flying smoothly and avoiding extreme maneuvers helps your gimbal deliver its best possible output.