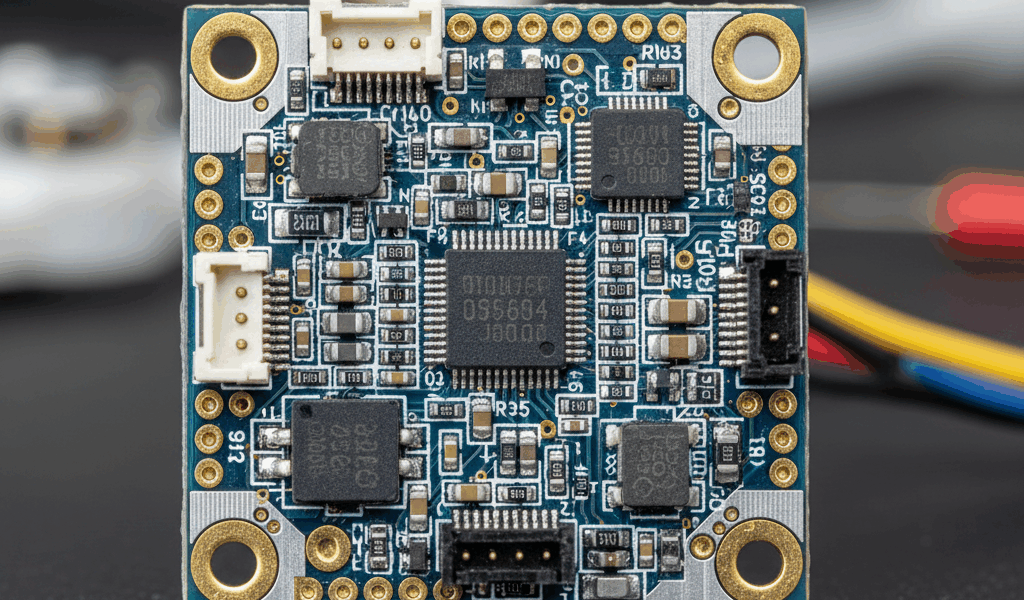

Flight controllers weighing under 5 grams serve as the brain of ultralight builds. These tiny circuit boards process sensor data, execute control algorithms, and coordinate motor outputs—all while contributing minimal mass to weight-critical aircraft.

What Flight Controllers Do

A flight controller translates pilot inputs into motor commands, making the drone actually flyable. Without sophisticated control processing, multirotor aircraft would tumble uncontrollably—they’re inherently unstable platforms requiring constant automated correction.

The core function involves reading gyroscope sensors dozens of times per second, detecting unwanted rotation, and adjusting motor speeds to counteract detected movement. This stabilization loop runs continuously, invisibly maintaining the level flight that pilots take for granted.

Beyond basic stabilization, modern flight controllers handle receiver signal processing, battery monitoring, LED control, blackbox logging, and numerous other functions. These integrated capabilities reduce component count, saving weight and simplifying builds.

Size Standards and Mounting

Micro flight controllers use standardized mounting patterns for frame compatibility. The 16x16mm pattern suits the smallest builds—Tiny Whoops and ultralight toothpicks where every millimeter matters.

Slightly larger 20x20mm mounting accommodates more capable boards with additional features. This size dominates the 2-3 inch class, providing adequate mounting area for full-featured controllers while fitting compact frames.

Larger 25.5×25.5mm and 30.5×30.5mm patterns exist but rarely appear in sub-5-gram boards. These sizes serve larger builds where weight constraints relax enough to permit bigger components.

AIO Boards: All-In-One Integration

All-in-one flight controllers integrate ESCs (motor speed controllers) onto the main board, eliminating separate ESC components. This integration dramatically reduces wire count, connection points, and total weight.

For ultralight builds, AIO boards often represent the only practical choice. Separate ESCs add weight through individual boards, mounting hardware, and additional wiring. AIO integration eliminates these penalties while simplifying construction.

Most sub-5-gram flight controllers use AIO configurations, combining flight control, 4-in-1 ESCs, and often receivers or VTX control into single compact packages. This integration epitomizes modern micro drone electronics.

Processor Capabilities

Flight controller performance depends heavily on processor capability. Faster processors run more sophisticated control algorithms at higher loop rates, improving flight performance.

STM32F4 series processors offer adequate performance for most applications, running stabilization loops at 4-8kHz. This processing handles standard flying comfortably while leaving headroom for features.

STM32F7 and H7 processors enable faster loop rates and more intensive processing. Racing pilots pushing equipment limits appreciate the responsiveness improvements these faster chips enable.

For casual flying and camera work, processor differences rarely matter practically. Pilots benefit more from proper tuning than from marginal processor upgrades.

Gyroscope Quality

Gyroscope selection affects flight quality more directly than processor choice for most applications. Better gyros detect smaller movements more accurately, enabling tighter control loops and smoother flight.

ICM-42688-P gyroscopes represent current premium options, offering excellent noise performance and high update rates. Many quality micro boards feature this sensor or comparable alternatives.

Budget boards may use older or less capable gyro sensors. Noise and drift from inferior gyros degrade flight performance regardless of other component quality. Gyro specifications merit attention during purchase decisions.

Soft mounting gyros (isolating them from frame vibrations) improves effective quality regardless of sensor grade. Many AIO boards integrate soft-mounted gyros, eliminating a separate build step.

ESC Specifications

Integrated ESC ratings determine maximum motor current, limiting power system options. Under-rated ESCs overheat or fail when paired with demanding motor configurations.

Most micro AIO boards rate ESCs between 5-12 amps continuous per motor. Smaller motors on 1-2S batteries need perhaps 5-8 amp ratings. Larger motors on higher voltages push toward 10-12+ amp requirements.

BLHeli_S firmware dominated ESC programming for years. Newer BLHeli_32 and BlueJay firmwares offer improved performance and features, though BLHeli_S remains adequate for most applications.

Receiver Integration

Some AIO boards include onboard receivers, eliminating separate receiver weight and wiring. Integrated receivers typically support common protocols like ExpressLRS or FrSky variants.

Receiver-equipped boards suit pilots committed to specific radio systems. Those running multiple protocols or preferring different receivers benefit from boards accepting external receiver connections instead.

Weight savings from integrated receivers typically span 1-3 grams—meaningful for ultralight builds but marginal for less constrained configurations.

Firmware Options

Betaflight remains the dominant flight controller firmware, offering extensive features, broad hardware support, and massive community knowledge. Most micro boards ship configured for Betaflight.

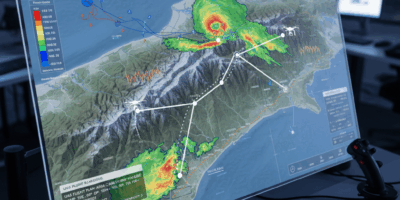

INAV targets GPS-equipped craft emphasizing navigation features. Some micro boards support INAV for autonomous flight applications, though full GPS integration adds weight.

Emuflight and other forks offer alternative tuning philosophies with varying popularity. Betaflight’s ubiquity makes it the safest starting point for most builders.

Configuration and Tuning

Flight controller setup occurs through configurator software—typically Betaflight Configurator for compatible boards. USB connection enables parameter adjustment, firmware updates, and feature configuration.

Basic setup involves motor mapping, receiver protocol selection, and mode assignments. These configurations get drones flyable but rarely optimize flight quality.

PID tuning adjusts control responsiveness and stability. Micro quads often fly acceptably on manufacturer defaults, though custom tuning improves handling for specific builds and pilot preferences. Numerous online resources explain tuning approaches.

Selecting Your Flight Controller

For Tiny Whoops under 30 grams, 16x16mm AIO boards with integrated receivers minimize weight. Prioritize gyro quality and ESC ratings matching your motor selection.

For toothpicks and lightweight builds, 20x20mm AIOs offer more features and easier soldering. Slightly higher weight permits more capable hardware choices.

Brand reputation matters for micro boards—quality control issues cause disproportionate problems on tiny components. Established manufacturers like BetaFPV, Happymodel, and HGLRC produce reliable micro electronics. Unknown brands risk frustrating quality failures.

Check community build threads before purchasing unfamiliar boards. Other builders’ experiences reveal issues that specifications don’t capture. The micro quad community actively shares hardware evaluations.